How younique solutions make

your application unique

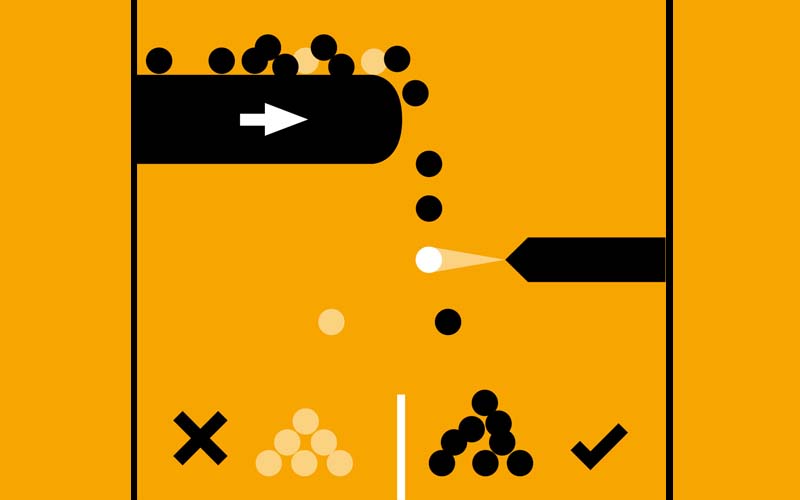

Our key objective is to contribute to the individual success of our customers with vision solutions. We have developed the innovative Open Camera Concept® with this in mind. Users can program their own application into NET cameras. Thanks to the ready-to-use development platform, you can arrive at your individual vision solution even without any expert knowledge. The vision solution will, of course, always remain fully in your hands. You can rely on NET – your partner with 25 years of experience and high-quality vision components – for assistance with the optimum configuration of all vision components. Whether you use existing or newly developed algorithms, you stand to benefit from this revolutionary development workflow in many different ways.

Vision solutions for industry and medicine

We support applications from machine manufacturers, system integrators and OEM providers with perfectly coordinated image processing components and individual vision solutions. We use our extensive know-how to optimize the combination of camera technology, optics and image processing for you. Our aim is to increase the efficiency of our customers’ value chain with vision solutions. Our motto: “The whole is greater than the sum of its parts.” (Aristoteles)

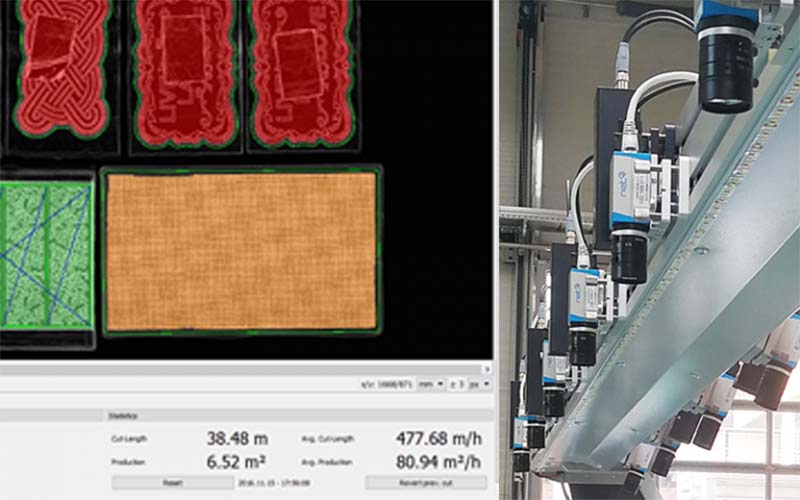

INDUSTRY

APPLICATIONS

For customers in the factory automation and quality assurance sectors, we provide standard cameras, embedded vision solutions, standard and customized optics and image processing solutions.

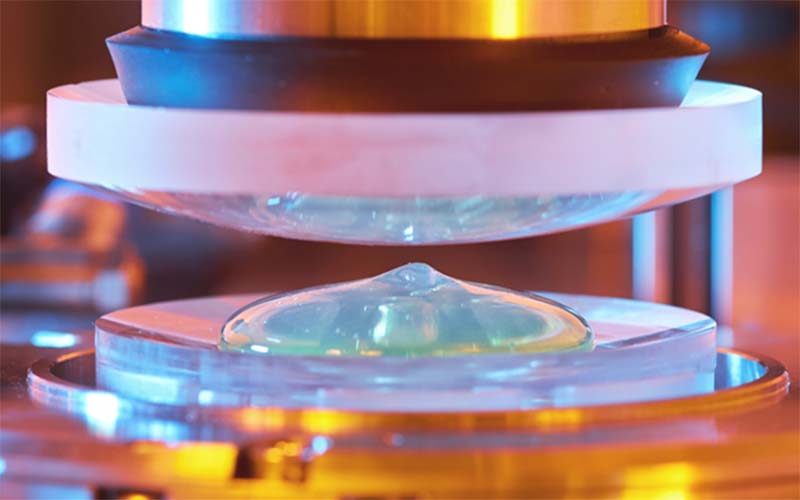

Medicine

APPLICATIONS

For manufacturers of medical video endoscopes and dental treatment units, we provide application-specific board-level cameras and vision solutions.

Fairs

April 22 - 26, 2024

Hanover, Germany

Hall 9 | Booth F76/1

Discover the ease of integrating smart cameras with AI in your machine vision applications. Save your free ticket and make an appointment with our experts!

NET News

Tutorial: Machine Learning with iam

This smart vision tutorial walks you through the workflow of bringing Machine Learning to the iam smart vision system. With the hardware-acceleration function, iam is designed to perform challenging image processing functions in real-time on the edge. See the straightforward workflow of creating unique smart applications for yourself. The video is protected. Please send a […]

Tutorial: The NET Open Camera Concept with iam

Learn how to use the resources of the in-camera FPGA for your hardware acceleration application. You can work on iam’s processor system with third party libaries like Halcon or Zebra Aurora TM Vision Studio or use open source software like OpenCV. In this session we cover how to implement hardware acceleration on iam using the Vitis platform. […]